Argar, the Italian producer of protective knits, has released a collection of antiviral and antibacterial fabrics. The company’s sales project director Laurence Balestrini explains more to Jessica Owen.

Italy was one of the first countries to shut down at the beginning of the year when the Covid-19 pandemic first hit. The worst affected area was probably the northern region around Milan, which is where the country’s textile industry is primarily based. Although many companies had to temporarily close down during this time, one business that has been able to carry on due to the nature of what it does is Argar srl.

Argar is one of the main European manufacturers of certified knitted fabrics that are earmarked for the production of personal protective clothing (PPE). The company’s fabrics feature characteristics such as fireproof, antistatic, high-visibility and protection from the electric arc, and because of the increase in demand for PPE recently, the business has been allowed to remain open.

On top of providing its usual PPE, and thanks to the coronavirus, Argar has recently released a new collection that is both antiviral and antibacterial.

The new line is called Avirtex and it offers a range of knitted fabrics characterised by combining two essential pieces of technology: a water-repellent treatment and HeiQ’s Viroblock – a unique solution of vesicle and silver technologies designed to inhibit the growth and persistence of bacteria and viruses.

“We started working with HeiQ around 14 years ago,” says Balestrini.

“When everything started back in February , we asked ourselves if we could help and so we developed the line with HeiQ. We started helping by making face masks as these were the first things that our customers demanded, but now we have the fabrics that can be used for other applications.”

The combination of the two finishes guarantees safer protection compared to standard fabrics for the same purpose. The water-repellent treatment prevents the passage of droplets through the fabric and HeiQ’s solution can then kill the microbes ensuring effective protection against their transmission and preventing contamination.

“Water repellency is something very easy to achieve and we have been using this technology for years,” he explains. “This is the first thing that everyone applies to a fabric because it acts as a barrier for droplets, but this is not enough for the virus – you need Viroblock to kill it, too.”

The company has dubbed the Avirtex line ‘the safest fabrics ever’ as they are capable of killing 99% of viruses between two to five minutes. Additionally, the fabrics can reduce the risk and speed of contamination and retransmission of pathogens from tissues, prevent the passage of droplets, and prevent the tissues from becoming host surfaces for the spread of viruses and bacteria because they slow down their growth and persistence.

What’s more, the collection is made with Oeko-Tex Standard 100 Class II fabrics and the finishes comply with the current REACH legislation. The Avirtex line also exhibits ‘excellent’ antiviral and antimicrobial activity even after several washes, as demonstrated by the antiviral activity analysis ISO 18184 test.

“We always work with certifications, whether it be for testing an electrostatic fabric or something else,” says Balestrini. “To have such a certification for a product to be antiviral, you have to test in the lab as it is more complicated.

“Our fabrics are certified to 30 washes at 60°C. And, at the moment, I have seen no one else in the world with this certification and a positive result.”

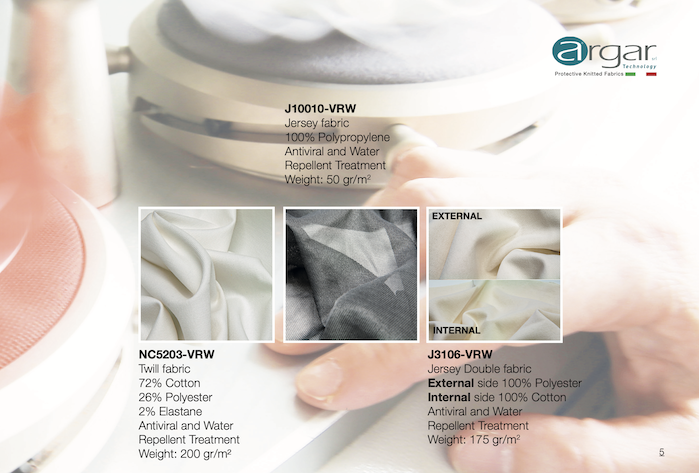

Specifically, the line currently comprises six fabrics: fleece fabric, popeline fabric, piquet double fabric, jersey fabric, twill fabric, and a jersey double fabric. The treatment is said to meet the safety needs of all professional figures who work closely with patients and customers in the medical sector, but also of personal services including hospital staff, general practitioners, dentists, hotel and restaurant workers, aircraft staff, school aprons and so on.

Balestrini says that the fabrics are not only suitable for PPE, but they can also be used for fashion. He says: “For sure, our biggest customers are in PPE, but we have other customers asking about the fabrics for different reasons. We have interest from the US and Europe asking about fashion and other applications because for just a few extra pounds people want the protection of Viroblock.”

One of the main advantages of the Avirtex line is that not only does it keep the wearer safe, but it also keeps them comfortable. Balestrini says that the treatment does not affect the weight or hand of the fabric and that the company is now even applying it to silk. He says: ” You can’t feel a thing.”

The Avirtex fabrics are now available and so are the company’s face masks. The feedback so far has been very positive, according to Balestrini. He says that his clients ‘like them very much’ and that ‘they are very comfortable’.

For obvious reasons, the collection has had a lot of interest recently , but Balestrini says that it won’t always be this way once a vaccine has been found for the virus. However, when that time comes, the company does not intend to stop selling Avirtex fabrics because it makes sense to have the choice of wearing something that is antiviral.

He says: “I think everyone will continue to wear face masks. And in many cases, like in hospitals, if you can have the choice of wearing a gown with an antiviral treatment then why not?”

Although the company had ‘many difficulties’ in the beginning, Argar is now in full swing when it comes to producing Avirtex fabrics. And customers can look forward to more choices in future as the business is continuing to expand the collection.

“We are definitely going to offer more fabrics,” Balestrini says. “Every time a customer asks for a different combination or a new development, we will follow that market demand, do the research and certification, and eventually add it to the collection. We are very proud to be able to produce and offer something that can keep people safe.”

WTIN – Make Informed Business Decisions

By Jessica Owen 19 August 2020