Green Project

In collaboration with LENZING AG, Argar has developed a line of protective fabrics featuring TENCELTM Lyocell fibers derived from sustainable sourced woods. These fibers are produced using an eco-friendly, closed-loop manufacturing process that efficiently transforms – with the least environmental impact – wood pulp into cellulosic fibers.

Our fabrics, made with TENCELTM Lyocell fibers combined with antistatic flame-retardant fibers, fully comply with the strictest EN standards that apply to the Personal Protective Equipment (PPE) and several other application fields.

What make these fabrics unique?

TENCELTM Lyocell fiber has gained a strong reputation for its environmentally responsible closed-loop production process. This process not only transforms wood pulp into cellulosic fibers with high resource efficiency but also has a low ecological footprint.

The solvent-spinning process reuses the solvent at a recovery rate of over 99%, in addition to allowing for the recycling of water used in the process.

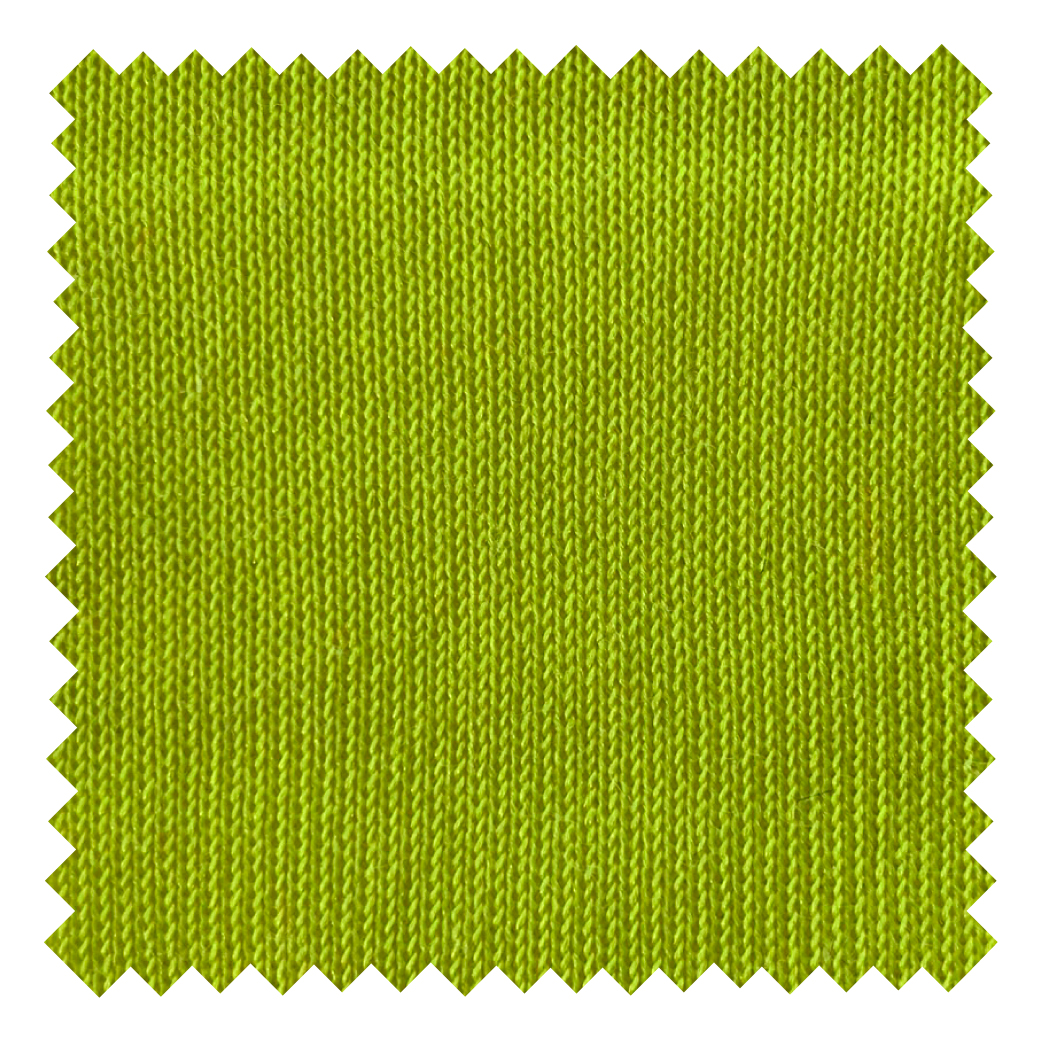

B9507

Rib

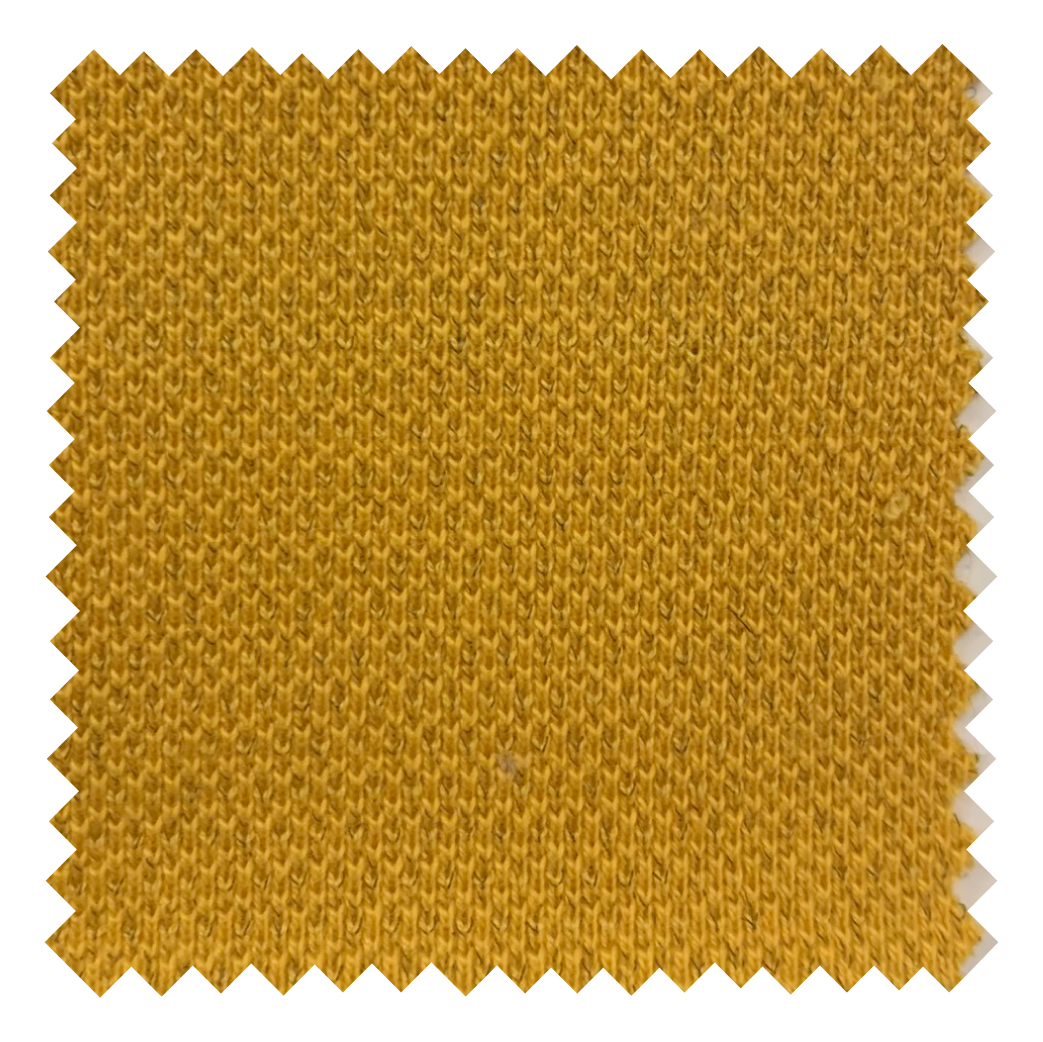

E926

Rib

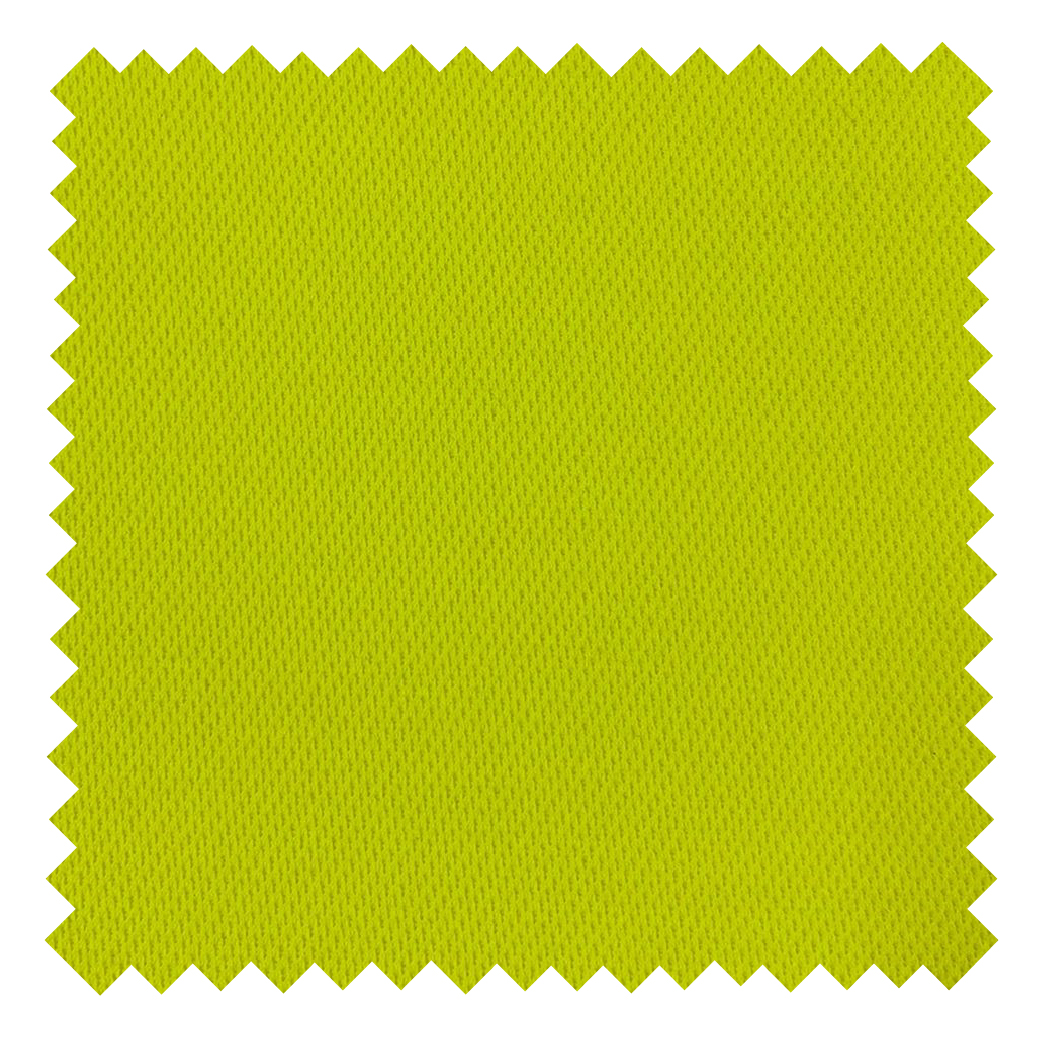

F9507

Fabric for Sweater

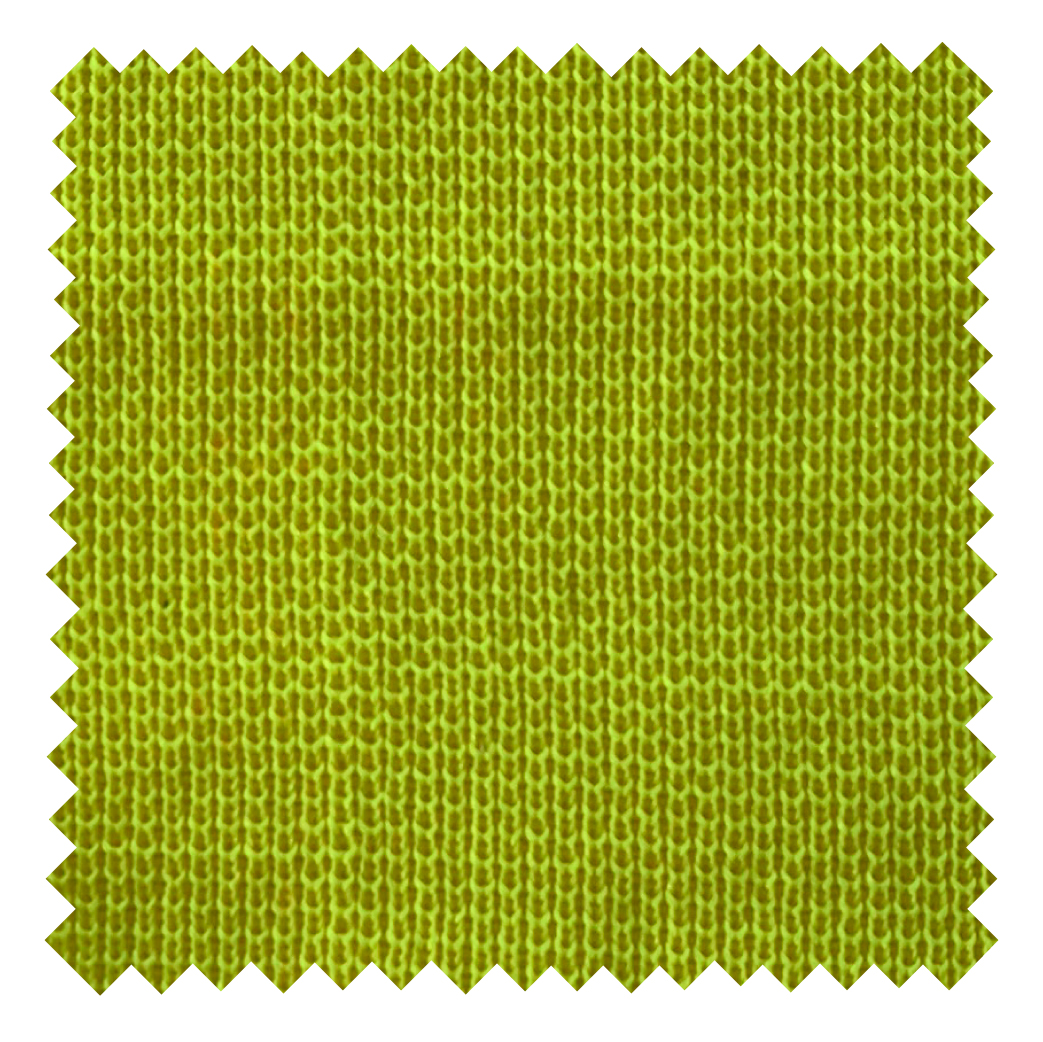

F9507-HV

Fabric for Sweater

J7372

Jersey

J7372-HV

Jersey

P9368

Piquet

P9368-HV

Piquet